How to Develop a New Electronic Hardware Prototype & Products for Your Company

If you think all products are perfected right from the first try, you might want to think again. The harsh truth is that some products have undergone thousands of prototypes and years of revisions before being officially launched. Seasoned developers understand the importance of making prototypes and testing them before their new products come to fruition.

Table of contents

If you are a hardware startup or a budding entrepreneur planning to introduce a new electronics product, you need to be familiar with the whole electronic hardware prototype development process. This will include the different types of prototypes you should create and the specific electronics prototyping tools available at your disposal. Continue reading below to find out more about the prototype and product development process:

Why is prototyping important?

There are two main reasons why prototyping is necessary, as follows:

Prototyping lowers the risk

Developing a product is an iterative process. The more prototypes you create, the more you will learn about the specific challenges you need to overcome in the next prototype, together with ways to enhance your original idea. After all, prototyping is equivalent to experience. The general rule of thumb here is that pinpointing areas that require improvement early in the development of a new product will help lower the cost of making these improvements.

RELATED: Why prototype DFM services are useful for product design at companies and firms

For instance, tweaking your idea will cost you nothing. However, if you discover errors after you have shipped the product, this might be the demise of your business. Developing prototypes will also give you a good idea of the cost of your bill of materials, or BOM, and as a result, an estimate of the expected retail price of the product.

Prototyping helps secure funding

Nothing will instill more confidence in your potential investors than presenting something tangible to prove your idea and its underlying concept. Considering how accessible rapid prototyping is today, you can no longer afford not to develop a good prototype of your product idea. In addition to proving your product concept, prototypes are also the best way to get a good feel of the finish and form of your new product, conduct testing under various conditions, and acquire feedback from users. Failure to test your product sufficiently before shipping it out is one of the main reasons many startups fail.

Benefits of prototyping for new electronic hardware development

A concept marks the beginning of every product idea, and it then slowly moves through the development process to the finished product, now ready for mass manufacturing. Many engineers often end up going in blind, so to speak, because they are unsure of the solutions that will and won’t work. They are also clueless about which components will be more cost-efficient and perform better. This is why hardware prototyping has a vital role to play when it comes to designing electronics. Here are some of the top benefits of electronics prototyping before you start to think about mass production:

RELATED: Different kinds of prototypes and how to use them for your design project

You can validate your concept

When someone wants to develop a new electronic hardware product, they only have a concept or idea of how a system or device should work. However, it is not always clear whether the actual product will be able to function as it is expected to. In such cases, you can falsify or prove your idea if you build a prototype first.

You can conduct a cost-efficiency analysis

It is never enough for businesses to prove that they can build hardware; cost-efficiency is essential in determining whether a consumer hardware product will succeed commercially. It is possible to evaluate the product development cost before beginning the prototyping phase. However, developing a prototype will allow you to specify the budget further. Assessing manufacturing costs at the earlier stages of development won’t be easy, but later prototype iterations can also answer this question.

You can cut your costs

Fixing any flaws in the design will be cheaper the earlier you spot them. Second, engineers can look for cheaper alternatives to reduce the final product’s cost during the prototyping stage.

You get a fresh perspective

It doesn’t hurt to have a new set of eyes when dealing with electronic hardware product development. In addition, a business can also outsource such tasks to a reliable third-party hardware design company since these firms have expertise and knowledge in this field.

You can speed up development with prototyping

At first glance, it is easy to assume that the services of product prototyping experts for electronics will be wasted time and money you could have otherwise spent on developing your final product right from the get-go. But producing test samples can cut back your overall development time and help reveal and remove the most pressing issues at the early stages.

RELATED: How to make a prototype for your new product design

You can raise more investment.

Companies sometimes prototype their electronic hardware product to present the device to prospective investors and persuade them to offer financial backing for further product development. Developing hardware, software, firmware, and electronics requires vast experience and highly trained and knowledgeable specialists. This is why it has become common practice to seek assistance from outsourced electronic prototyping firms. Many companies choose to outsource both development and manufacturing. It is expected that the global market of electronic contract design and manufacturing will be worth hundreds of billions of dollars by 2027.

You can test components

Engineers can split complicated designs into simpler parts during the prototyping stage to allow individual testing. This helps spot possible issues and identify better solutions.

8 Different types of prototypes

All new products require multiple iterations of prototypes before you are finally ready for the mass manufacturing of your product. Here are the different types of prototypes you might need on your way to launching your product to the market:

POC prototype

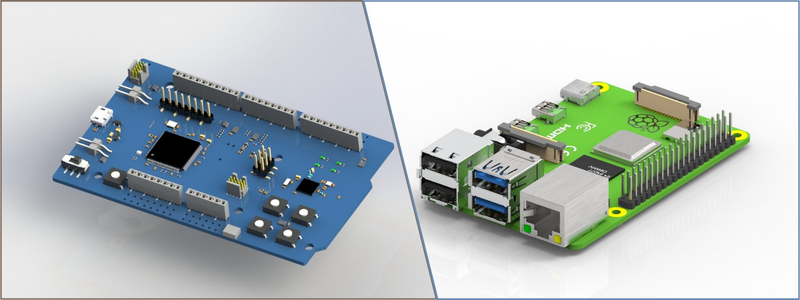

As the name implies, a POC or proof of concept prototype is an early-stage prototype that proves the product’s basic concept. It is scarce for a POC prototype to have the same function and look as the final product. It only has one goal: to prove the product’s fundamental concept as cheaply as possible. A POC prototype for most electronic hardware products will be made using an electronics development kit.

Many electronic products need either a microprocessor or a microcontroller. This prototype is often used to identify whether a new product idea is practical, and customers rarely see it. Developing a POC prototype is the most sensible choice if you have fundamental queries about your product’s ability to address the intended problem.

RELATED: How to reduce painful product development costs for your company

Looks-like prototype

Looks-like prototypes focus on the product’s look, form, aesthetics, and feel. You will use different prototyping techniques for these prototypes, including clay, foam, CNC machine design services, 3D printing, and injection molding. Many of these prototypes are made using the additive process of 3D printing technology, which means that the material will be added in layers to create the final shape. The focus of a looks-like prototype is the product’s exterior, which will be made of metal or plastic.

Although it might seem too simple, never take old techniques such as clay and foam for granted, as these can come in handy during the early stages. These technologies let you cheaply and quickly turn a concept into something you can hold in your hand. Using clay or foam can be the easiest and cheapest method for experimenting with your product’s feel, shape, and size. For this prototype, you can use 3D printing and CNC machining. 3D printing, in particular, has three main types: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Works-like prototype

Works-like prototypes focus on the product’s functionality, and for most electronic products, this pertains to their internal electronics. POC prototypes can be considered the early version of works-like prototypes. However, you will jump to a POC prototype’s production-level counterpart this time. This means that you will now abandon using development kits. Instead, you will need to hire a PCB design company to develop a custom PCB, or Printed Circuit Board, to hold and connect your product’s discrete electronic components.

Significant experience in engineering design is necessary to develop a custom PCB for works-like prototypes. You will save money on development fees if you are lucky enough to have such skills. It can be costly to hire engineers, and custom PCB development is often the highest development cost you will face.

RELATED: Top tips to create impactful prototype designs for company products

Engineering prototype

Also often referred to as a works-like-looks-like prototype, this prototype is the first in which functionality and appearance come together. Once you have developed an engineering prototype, you will have something of sufficient quality to present to potential investors and customers. This is when it becomes more practical for you to look for outside investors. By this point, you will also have moved past most of the risks associated with manufacturing and engineering. As expected, investors appreciate this risk reduction. Engineering prototypes are close to production prototypes but are not yet prepared or tested for mass manufacturing.

Pre-production prototype

Pre-production prototypes are essentially engineering prototypes developed by a prototype design engineer that is optimized for manufacturing and close to the final product your target customers will see. Most of the time, a pre-production prototype also needs to include the product’s retail package if it is sold through retail outlets. Even though the pre-production prototype might function the same way as the engineering prototype and look very similar, manufacturability is the main difference between the two.

During a product’s development, most entrepreneurs underestimate the work required to migrate from the prototype to a product that can be competently manufactured. The pre-production prototype requires injection molding to manufacture your product’s enclosure in higher quantities. As expected, the process of injection molding begins with mold creation. These molds are machined from metal, with the metal’s hardness determining the cost and lifetime of the mold.

RELATED: 6 Reasons you need to prototype your new product design

Engineering validation test or EVT

After you finish your engineering prototype, it is time to start testing it to confirm that it works according to the exact specifications. The initial stage of this testing is known as Engineering Validation Testing, or EVT. The electronics are the main focus of this testing stage. Most of the time, around 10 to 50 units undergo testing during EVT. EVT includes not only tests of basic functionality but also different stress tests to guarantee that there are no hidden issues. It includes EMI, thermal, and power testing. The primary purpose of EVT is to validate that the prototype meets the reliability, function, and performance specifications.

Design validation test or DVT

The Design Validation Test, or DVT, is probably one of the most difficult phases. Its purpose is to ensure the product adheres to the necessary environmental and cosmetic specifications. More units will be required here than at the EVT stage—usually 50 to 200 units. These units will undergo aggressive testing, including waterproofing, fire, and drop testing. Validating the product’s durability to withstand daily use is among the main goals of DVT. This testing phase is often the time to obtain electrical certifications, such as UL, RoHS, FCC, and the like.

The time and cost involved in obtaining the required electrical certifications will delay completing the DVT phase. The purpose is to ensure that no other design changes will be required after certification testing starts. Of course, when issues are discovered during certification testing, there might be a need to modify the design to correct them accordingly.

Production validation and testing or PVT

The first official production run, the PVT stage, is where you will establish a pilot production line with the priority of production process optimization. The main focus here is to improve your quality control process, assembly time, and scrap rate by optimizing the production line while ensuring no further changes in the product’s design are required, except when a severe problem has been identified. It is also typical to have a smaller pilot production run of a few hundred units, and these can become the first units you sell if no issues are discovered.

RELATED: Guide to new electronics prototyping for hardware startups & design companies

Stages of developing new electronic hardware prototypes and products

Whether you are an aspiring product developer or have already released a few products, you might know that launching a new physical product is a long and sometimes challenging journey. Even though it is not a secret that hardware comes with some complexities, it has now become more straightforward than ever for small electronic prototyping and design companies and individual developers to develop great new electronic devices. This short guide aims to teach you the steps in developing new electronic products. It aims to cater to small companies, startups, and entrepreneurs preparing to build their first-ever hardware product.

The good news is that you don’t need any previous electronics design knowledge to grasp the following points. However, it will still be much easier for you to understand everything if you have some technical background in engineering, computers, or other fields of science. Just note that while the different stages are presented here in a step-by-step fashion, product development is not a smooth, linear progression. You might sometimes find yourself taking a couple of steps back for each action you take forward. Avoid feeling frustrated if this happens, though, since this is still a part of the journey.

RELATED: Cost to design a new electronic product, develop PCB hardware & prototype rates at firms

The first phase: deal with the initial legwork

Before proceeding to the actual steps involved with product concept design and development services, it is important to have a quick overview of the preliminary work required. Sadly, many entrepreneurs skip these essential initial steps because they prefer to dive right into product development. You can ignore these early steps, but you do so at your own risk.

Market research, product validation, and patents

It is important to look into your competition and check whether your product has an existing market in the first place. When entrepreneurs go about their competitive research, one common misconception is to assume that it is bad if they find any competition. The truth is that most entrepreneurs end up panicking, thinking that their project will all be for nothing once they discover that there is already an existing solution. However, it is good to have some competition because it shows that your product idea has a target market.

After you have confirmed that there is an existing market for your new product, it is time for you to verify whether people will be interested in buying it. For example, one method of validating your idea for a new product is to create a sales flyer that you can distribute to potential customers and prospective retailers offering similar items. You can then ask them to give feedback regarding your tech product. Another great way of testing your idea is setting up an online sales page. Validation can also be done through crowdfunding.

RELATED: What is crowdfunding – understanding the basics

The main secret here is to share your product idea with as many unbiased people as possible who can provide honest reviews and feedback. At this point, you might be wondering about the patent. Won’t you need one before it is safe for you to share your product with other people? One of the most common mistakes new entrepreneurs make is being too secretive. In reality, no hardware startups have failed because of having their idea stolen. Instead, entrepreneurs fail because they don’t succeed in marketing their products.

But it is understandable to have some privacy concerns, and that’s why many people hire a patent design firm before anything else. However, patents can be expensive and time-consuming to obtain, and just when you are starting development is not the best time to get one. Instead, getting a Provisional Patent Application (or PPA) in the US is recommended, with other regions probably having something similar available. A PPA costs just a couple of hundred dollars and can offer protection for your product for a year. It also saves you from the need to work with a patent attorney at this point, which can be an added expense.

Make your product simpler

Ask any seasoned consumer product developer, and they will surely tell you that one of the most valuable lessons they have learned is making your device as simple as possible. This simplification process must be embraced to have a more realistic shot at marketing your product promptly without draining your budget.

RELATED: Accessible design: better products for everyone

Beware of product complexity

Many entrepreneurs, as well as the majority of engineers, don’t understand all the effects of different product features. Adding a new feature, even the most minor, can cause a drastic increase in the cost of development and the time it will take for you to market the product. Something as simple as a button’s specific position, for instance, can waste several thousand dollars when it requires the creation of additional, pricier injection mold & casting services. The real catch here is that unless you have a good understanding of the entire manufacturing and development process, it might not be easy to determine the future effects of each product decision.

If outsourcing your product development, it is important to remember that asking your main developers to simplify your product might lead to a conflict of interest. This is because you will pay them more if your product becomes more complex. Instead, you might be better off working with independent professionals who can help make your product simpler and have a good understanding of the long-term effects of your initial product decisions.

RELATED: 8 Tips companies use to simplify design manufacturing or design for manufacturing

Come up with your POC prototypes

By this time, you have already proven that your product has an existing market, and you have done everything possible to simplify your product concept. The next question you need to answer is whether your concept addresses the intended issue as expected. This is the primary objective of the earlier-discussed POC prototype, or the early prototype developed using off-the-shelf components.

The POC prototype lacks a custom electronics design and is often based on a development kit. Once again, it is essential to remember not to start with the entire development right away. However, what makes a POC prototype different is that, most of the time, it is not that expensive to develop. Sadly, a POC prototype is seldom something you can launch in the market. It would involve a high cost of production, its physical size is too large, and its appearance is far from ideal.

Second phase: pick the right strategies for product development

Startups and entrepreneurs have five options for new hardware product development. You may lack the technical knowledge for proper product development management and judging the work quality. If this is the case, it is a must to work with a technical advisor, no matter the development strategy you choose. Your technical advisor will guide you in making important technical decisions and offer oversight of your key developers. Although you might be an experienced engineer yourself, it will work to your advantage to have an advisor who understands the whole process, from the initial idea to launching your product on the market.

RELATED: Choosing the right manufacturing materials

1. Develop your product yourself

This is seldom an efficient strategy on its own. Only a handful of people have the necessary skills to develop an electronic product ready for the market all by themselves. Yes, you might be an engineer, but are you also an expert in programming, electronics design, injection molding, manufacturing, and 3D product modeling services? Chances are you are not, mainly since many of these specialties consist of several sub-specialties. It is the case that the more necessary skills you have, the further you will be able to take your product development by yourself, allowing you to save more money as a result.

However, while using all your skills is a good idea, you shouldn’t take it too far. It will be a costly mistake if your sub-expert skills mean you develop a less stellar product. Further, it will take time to learn new skills, which might ultimately increase the time required to market your product. It wouldn’t hurt to seek help from experts who can fill in the gaps in your expertise but make sure that you are still involved in all the major decisions.

2. Look for technical co-founders

It would be a wise move on your part to look for a technical co-founder if you happen to be a non-technical co-founder yourself. At the very least, one of your startup’s founders must have a good grasp of the product development process to manage it properly. If your plan involves seeking professional investors who can provide outside funding down the road, it is necessary to have a team of founders. Expert startup investors know that a team of founders is more likely to succeed than a solo founder.

RELATED: Top 101 new product design and development firms for services in the US

The perfect co-founder team for most hardware startups consists of a marketer, a programmer, and a hardware engineer. However, while it may sound like having co-founders is the best answer to your problems, note that this might also come with several serious downsides. For starters, looking for co-founders is complex, and it will probably take up a lot of time that you could otherwise spend on your product’s development. Looking for co-founders isn’t something that you should do rashly.

It is essential to take time to find the perfect match for you. Your co-founders shouldn’t only complement your skills. It is also crucial that you like them as a person. If you consider that this partnership is like being married to your co-founder for several years, that will help you understand why it is vital that you get along with them well. However, take note that having co-founders means your company equity will be reduced, as all of the company’s founders must have equal equity in the business. If you are currently on your own, be ready to share your company with your co-founders.

RELATED: 18 Companies that use crowdsourcing for new product design & prototype innovation

3. Outsource the process to freelance engineers

A straightforward way to fill in the gaps in the technical ability of your team is to outsource the job to freelance design engineers. Remember that many products will need several engineers of various specialties, which means that you will be managing a few engineers on your own. A founding team member will ultimately become the project manager.

Ensure that you hire an electrical engineer with the necessary experience and skills in designing the specific type of electronics your product needs. With electrical engineering services being a vast field of study, not all engineers are experienced with circuit design. As for 3D designers, ensure that you look for someone who is experienced with injection molding technology. If you don’t, you will probably get a product that you can prototype, but that cannot be mass-produced.

4. Outsource to a trusted development firm

Some of the most prestigious and reliable design firms can develop fantastic product designs. Unfortunately, their rates can be insanely expensive. Startup companies might want to stay away from bigger design firms as most of them will charge you over $500,000 for complete product development. And even if your budget allows you to pay for the pricey product development firms, avoid it at all costs. Instead, you might try looking for smaller, less popular, but equally trustworthy design firms that can help you with your product development at reasonable rates. The prices of these smaller firms often fall closer to freelancer rates, with quality procedures and proper oversight in place.

RELATED: How crowdsourcing helps inventors and companies innovate and grow

When working with these product designers, you should never assume that you can simply let someone deal with the development process while you are waiting on the sidelines. Anyone with this misconception ends up getting burned and loses a lot of time and money. You must have firsthand involvement in the development process and a good understanding of the basics together with the different design tradeoffs being made.

5. Join forces with a manufacturer

An avenue worth considering is joining hands with an overseas manufacturer with previous experience in making products similar to yours. Large manufacturers often have development and engineering departments working on their own products. Consider yourself lucky if you can find a manufacturer that already develops products similar to yours. This company might also be able to handle everything on your behalf, from development to engineering, prototyping, mold production, and finally, manufacturing.

This particular strategy can cut down your upfront costs for developing your products. However, manufacturers will still amortize these costs, and you will need to add an extra amount for every product during the initial production runs. It basically works the same as an interest-free loan that lets you pay back the manufacturer for your development costs little by little.

RELATED: Contract manufacturing services vs. manufacturing services

While this might sound straightforward, there is still a catch here: you will have to entrust everything about your product to just one company. You can expect them to want an exclusive manufacturing agreement until they recover their costs. This means you won’t be able to migrate to a more affordable manufacturing service once there is an increase in your production volume. It is also important to remember that most manufacturers may prefer having part or even all of your product’s intellectual rights.

Third phase: develop your product’s electronics

There are six steps involved in developing your product’s electronics, as follows:

1. Craft a preliminary production design

A preliminary production design should be the first step when developing your new electronic hardware product. This one is different from the POC prototype discussed earlier. A POC prototype is often made using development kits. These can come in handy in proving that your product concept can solve the intended problem. However, a POC prototype is not a production design. It is very rare to go to market with your product still embedded in the development kit. The focus of a preliminary production design is the production components of your product, its features, profit margin, components, manufacturability, and development feasibility.

RELATED: Which manufacturing technology is right for your new invention?

A preliminary production design can be used to estimate each cost required by your product. It is a must to have an accurate knowledge of the costs to develop, program, prototype, manufacture, scale, and certify the product. Preliminary production designs answer several key questions. Is it possible to develop your product? Does your budget allow the development of the product? How long would it take you to develop your product? Is your product feasible for mass production? Can you earn a profit from selling your product?

Many entrepreneurs often make the grave mistake of skipping this preliminary production design step. Instead, they proceed straight to the schematic circuit diagram. However, if you do so, you might waste your hard-earned money and effort on a product you cannot develop, manufacture, and sell at a profit.

RELATED: Top 7 ways to lower mass-manufacturing costs & lower rates at new prototype firms

- System block diagram: When developing your preliminary production design, you must first define the system-level block diagram. The diagram will specify the function of every electronic component and the interconnection of all the functional elements. Many products need a microprocessor or microcontroller with different components, such as memory, sensors, and displays that interface with the microcontroller through different serial ports. Developing a system block diagram will make it easier to determine the number and type of required serial ports. It is an important first step in choosing the microcontroller that suits your product.

- Choose production components: The next step is to pick the different production components, such as connectors, displays, sensors, and microchips, depending on your product’s target retail price and desired functions. This will let you develop a preliminary BOM. There are several popular electronic suppliers in the United States. You can buy many electronic components in single units for initial testing and prototyping or thousands of units for low-volume manufacturing. You can save more money if you buy some components straight from the manufacturer after reaching larger production volumes.

- Estimate the cost of production: It is now time to estimate your product’s production cost, also known as the “cost of goods sold” or COGS. Knowing how much you will spend on manufacturing your product as early as possible is important. It is also imperative to determine the manufacturing unit cost of your product to identify the best sales price, the inventory cost, and your profit.

RELATED: Smart manufacturing using CAD design is the future for OEM’s

Of course, your chosen production components will significantly influence your manufacturing cost. However, to get an exact estimate of your manufacturing cost, you also need to add the printed circuit board (or PCB) assembly cost, final assembly of the product, product testing, scrap rate, retail packaging, duties, logistics, warehousing, and returns.

2. Schematic circuit diagram design

For the second step, you will require the help of a schematic design expert to create the schematic circuit diagram according to the system block diagram you made in the first step. This schematic diagram will show how components connect with each other, from the microchips to the resistors. While a system block diagram mainly focuses on the product’s higher-level functionality, these little details are the focus of the schematic diagram.

A total lack of functionality can result from something as minor as a misnumbered pin on the schematic’s component. Most of the time, every block of the system block diagram needs a separate sub-circuit. The different sub-circuits will then be connected to create a complete schematic circuit diagram. An electronics design software program will also be used to make the schematic diagram and ensure that it doesn’t contain any errors.

RELATED: How to design effective assembly drawings for consumer products and manufacturing companies

3. Design the PCB

After you finish the schematic, it is time to design the PCB, the physical board holding and connecting all the electronic parts. The development of the schematic circuit and system block diagram is mainly conceptual in nature. However, a PCB design takes the concept into the real world. When designing the PCB, the designer uses the same software for creating the schematic diagram. This software features different verification tools to guarantee that the PCB layout will meet the design rules for the chosen PCB process and that the PCB will match the schematic.

Generally speaking, if the product is smaller and the components are tightly packed, creating the PCB layout will also take longer. If your product routes huge amounts of power or provides wireless connectivity, there will be a more time-consuming and critical PCB layout. The most crucial parts for many PCB designs include wireless circuits, high-speed signals such as data/address lines and crystal rocks, and power routing.

RELATED: Hiring the best electrical engineers & freelance PCB designers

4. Generate the final BOM

Even if you have already developed a preliminary BOM by this time as a part of the initial product design, a complete production BOM is still necessary. The primary difference between these two lies in the different affordable components, such as capacitors and resistors. These components are often low-cost, so they are not individually listed in the preliminary Bill of Materials. However, for the actual PCB manufacturing, you will need a comprehensive BOM that lists all the components. The schematic design software often creates this BOM automatically. The BOM contains the quantities, part numbers, and specifications of all components.

5. Order your PCB prototypes

Electronic prototype development is a process that involves two steps. The initial step is the production of the bare PCBs. The circuit design software will let you output your PCB layout in the format known as Gerber with a single file for every PCB layer. You can send the Gerber files for small-volume runs to a rapid prototyping firm. You can also send the same files for a higher production volume to a larger manufacturer. The second step is to solder all the electronic components on the board. You can output a file from the design software that will show the exact coordinates of each component added to the board.

RELATED: PCB design engineering rates, costs & freelance service prices for new company products

The assembly shop will then be able to automate the soldering of all PCB components fully. The most affordable option is having your PCB prototypes produced overseas. Even though it is often recommended to have your prototypes made close to home to help reduce delays in shipping, minimizing the costs is more important for most entrepreneurs. Getting the assembled boards often takes one to two weeks unless you opt for a rush service, which is not always recommended. The steps below are a summary of what transpires during PCB production:

- The process starts with the laminate core crafted from woven glass epoxy, which acts as the insulator between the conducting layers while giving the board the physical strength it needs.

- The single-sided boards are made up of a single laminate core with one side featuring a copper layer. The double-sided boards comprise a laminate core, with each side having copper layers. Several layer boards are made of a stack-up of alternating laminate core layers with copper layers. Many boards use six, four, two, or possibly even eight conducting layers.

- The layout design for every conducting copper layer is plotted on film using a laser and applying “resist,” a chemical sensitive to light. The copper layers are exposed to the high-intensity ultraviolet light shining through the film. The light hardens the “resist” layer on top of any copper pads or traces.

- The copper layers undergo processing through a chemical solution that removes any leftover “resist” layer that the ultraviolet light couldn’t handle. All that then remains is the hardened “resist” material on top of the desired copper pads and traces. Another chemical is used to remove the exposed copper that “resist” didn’t cover. The hardened layer of “resist” is removed so that only the desired copper is left to form the pads and traces.

- The next stage is the lamination process, which bonds together all the layers to create the stacked PCB.

- The PCB stack-up is drilled through with holes to form the vias used for connecting signals on various layers. The holes for the through-hole components are drilled as well. But generally, it is best only to use Surface-Mount Technology (SMT) components to lower the soldering costs.

- The visible metal surfaces and the holes’ inner walls will now be deposited with copper. Extra copper will also be electroplated on all the visible copper surfaces.

- With the bare PCB now complete, the next step is to insert and solder all the electronic parts. A robotic piece of equipment named the pick-and-place machine features a vacuum system that picks the components up and puts them on the exact spot on the PCB. The parts are temporarily held in place using a solder paste, which is a sticky mixture of flux and solder.

- The boards are finally run through the reflow oven to melt the solder paste and create a permanent electrical connection between the PCB pads and the component.

RELATED: Tips for PCB design services creating new products

6. Evaluate, program, debug, repeat

At this point, you will need to evaluate the electronics prototype. Take note that it is very rare for the initial prototype to work as flawlessly as you hope it will. More often than not, you will need to go through numerous iterations before finalizing the design. This is when you should identify, debug, and address any problems with the prototype. Forecasting this stage can be tricky in terms of both time and cost. Of course, it will take time to pinpoint where any bugs come from and the best way to fix them.

Testing and evaluation are often done simultaneously with the programming of the microcontroller. However, before you start programming, you will want to conduct some basic testing to confirm that there are no significant problems on the board. Almost all of today’s electronic products feature a microchip known as a microcontroller Unit or MCU. The MCU serves as the brains of the product. The microcontroller is the same as the microprocessor found in smartphones or computers.

The microprocessor is excellent for the swift movement of large quantities of data, while the microcontroller functions better at controlling and interfacing devices such as motors, displays, switches, sensors, and the like. The microcontroller is essentially a simplified version of the microprocessor. The microcontroller also needs to be programmed to perform the preferred functionality. Most of the time, microcontrollers are programmed in the frequently used computer language known as C. Called firmware, the program is kept in a reprogrammable permanent memory often internal to a microcontroller chip.

RELATED: What are electronic manufacturing services (EMS) for new products & prototype design?

Fourth phase: enclosure development

This stage covers the creation and prototyping of custom plastic pieces, which as a minimum, includes the enclosure holding everything together for most products. You will need to work with a electronics enclosure design expert or an industrial designer to develop custom-shaped metal or plastic pieces. Hiring an industrial designer will work to your advantage if ergonomics and appearance are crucial for your product. Industrial designers are engineers responsible for the sleek and cool looks of portable devices such as iPhones. On the other hand, if the product’s appearance doesn’t matter that much, working with a 3D modeler might be enough, not to mention that they often charge lower prices than industrial designers.

Develop the 3D model

Creating a 3D computer model is the first step to developing the exterior of your product. There are several software packages you can use to create your 3D models. After the 3D modeling or industrial designer has finished the 3D model, it can be transformed into physical prototypes. You can also use the 3D model for marketing, particularly before the availability of your functional prototypes. If your 3D model will be used for marketing purposes, you need to create a photorealistic version of the model. You can even develop a photorealistic 3D animation.

RELATED: What are industrial design rates & costs at product design services firms?

Take note that you might need to work with a separate 3D product animation company that can ensure that the 3D models will look realistic. However, the main risk in developing your enclosure’s 3D model is that you might get a design you can prototype but cannot manufacture in large volumes. Your enclosure will ultimately be produced by the method known as high-pressure injection molding.

It can be quite complicated to use injection molding to develop a part for production, as there can be numerous rules to follow. Meanwhile, 3D printing allows the prototyping of just about anything. This is why hiring someone with a complete understanding of the design requirements and complexities of injection molding is better.

Purchase a 3D printer or order prototypes of the case

Plastic prototypes are developed using either a subtractive process or the more common additive process. An additive process, like the case with a 3D printing design professional, can create prototypes by stacking thin plastic layers to form the final product. So far, additive processes are the most common due to their ability to make almost anything imaginable. Subtractive processes, such as CNC machining, take a block of solid production plastic and carve out the final product. The main benefit of subtractive processes is that they use a plastic resin that matches the plastic you will use for the final product.

RELATED: What is 3D printing? A beginner’s guide

However, while this is important for certain products, it is unnecessary for most. A special prototyping resin is used with the additive processes, which might feel different from a production plastic. The resins used in these additive processes have dramatically improved, although they don’t match those production plastics used in injection molding. It was stated earlier, but it is worth repeating: prototyping processes such as subtractive and additive are entirely different from injection molding, the technology used for production.

It is never wise to create prototypes that are impractical to manufacture, particularly with additive manufacturing services. At first, there is no need to make your prototype follow all the injection molding rules. However, you need to consider this to easily transition your design to injection molding. Many companies can take the 3D model and transform it into a physical prototype.

You can also consider buying a 3D printer, particularly if you foresee requiring various iterations to perfect your product. You can buy these 3D printers for just a few hundred dollars, letting you develop as many prototype versions as you need. The key benefit of buying a 3D printer is that it lets you iterate the prototype almost instantly, cutting your time to market.

RELATED: 6 Ways 3D printing will change the world

Assess the prototypes of the enclosure

At this point, you need to assess the prototypes of the enclosure and tweak the 3D model as needed. This will require a few prototype iterations to achieve the right enclosure design. Even though 3D computer models allow you to envision the enclosure, nothing can beat the experience of holding a real and tangible prototype of the prototype design firm in your hand. Most of the time, there will be both cosmetic and functional changes you will want to make after you develop your first actual prototype.

It is advisable to plan for the need for several versions of the prototype to get things right. It is not necessarily cheap or easy to develop plastic for a new product, especially if aesthetics is crucial for your product. But the real costs and complexities pop up once you transition to full production from the prototype stage.

RELATED: 3D models of electronic enclosures by freelancer designers on Cad Crowd

Shift to injection molding

Even if the electronics are possibly the most expensive and complex part of the product to develop, the priciest to manufacture is plastic. It is costly to set up production of your plastic parts using injection molding. Injection molding is an old manufacturing method that is still commonly used to make plastic products, and it is critical that you understand the process. You begin with a mold consisting of two steel pieces held together with high pressure. This mold features a carved cavity in the desired product’s shape. The hot molten plastic will then be injected into the mold. The main advantage of injection molding technology is that it is affordable to produce millions of similar plastic pieces.

The injection molding technology of today uses a large screw to force the plastic into the mold using a high process, which was developed in 1946. Injection molding, unlike 3D printing, is primitive. Injection molds can be very efficient at producing large quantities of the same thing at a relatively low price per unit. Unfortunately, these molds themselves can be pretty expensive to create. In fact, a mold made for producing millions of units can easily cost you hundreds of thousands of dollars. The cost is mainly because of the high-pressure injection of the plastic, which can be pretty tough on the mold.

Molds are developed using hard metals to help them endure these conditions. The metal required will be harder if more injections are needed, thus resulting in a higher cost. Aluminum molds, for instance, can be used to make a few thousand units. The aluminum is soft, which means that it can degrade fast. However, this also means it is easier to make into a mold, meaning the price will also be lower, at around $1,000 to $2,000 for a simple mold. When there is an increase in the mold’s intended volume, the required metal hardness and the cost will also increase.

The lead time for mold production will also increase with hard metals such as steel. With t will take the mold maker longer to carve out (or “machine”) a steel mold than an aluminum one. Sooner or later, you can increase your production speed using several cavity molds. These will let you produce numerous copies of your part with one plastic injection. However, you should avoid jumping into many cavity molds until you are done working through any changes to your first molds. It would be practical to run at least a few thousand units before upgrading to more cavity molds.

Fifth phase: product certification

Every electronic product on the market must have different types of certification. The necessary certifications may differ depending on the country or region where you plan to sell your product. Although most of these are electrical certifications, most of the time, you need to complete them on the final product with the enclosure included and not on the bare electronics alone.

You have to design the product right from the beginning while considering and taking note of these certifications. However, the actual certifications will generally be completed as late as possible while you set up manufacturing. If you have your product certified earlier than necessary, any changes in the design will probably leave you with no choice but to have it certified again. This is why it is better to wait until you have finished finalizing your product with no further changes anticipated.

RELATED: How to evaluate your new product design & company tips to improve prototypes

Since certifications are a complicated topic, it is recommended to seek help from a certification expert before going too deep into the product development process. There are a lot of helpful tips and tricks that can significantly lower your certification costs if you implement them right from the beginning. Below are some of the top certifications required in the European Union, Canada, and the USA:

CE or Conformité Européene

The CE certification is required for most electronic products sold in the EU or European Union market. This is similar to the UL and FCC certifications mandated in the US.

FCC or Federal Communications Commission

The FCC certification is imperative in the United States, covering all types of electronic products. Every electronic product emits a certain level of electromagnetic radiation or radio waves, and the FCC has to ensure that these products won’t interfere with wireless communication. The FCC certification has two main categories. The specific type required for your particular product depends on whether it comes with wireless communication capabilities, for example, Wi-Fi, Bluetooth, or ZigBee.

RELATED: Want tips on how to create a new product?

Products that feature functionality for wireless communication are classified as intentional radiators by the FCC. On the other hand, products that don’t intentionally produce radio waves are categorized as non-intentional radiators. An intentional radiator certification can cost you approximately ten times as much as the certification for non-intentional radiators. You can consider the initial use of electronic modules for any of the wireless functions of your product. This will let you get by with just the non-intentional radiator certification, which can help you save a minimum of $10,000.

Lithium battery certifications (IEC62133, UL1642, UN38.3)

Several serious safety issues are associated with rechargeable polymer or lithium-ion batteries. These can easily burst into flames and even cause a fire if they are overcharged or over-circuited. You may remember the Samsung Galaxy Note 7’s double recall because of this problem or those horror stories of several hoverboards that burst into flames. These safety concerns are the very reason why it is imperative to certify rechargeable lithium batteries.

For many products, it is recommended to use off-the-shelf batteries that already bear these certifications, but this will limit your options. For example, many lithium batteries don’t have certifications, mainly because many hardware companies opt for custom-designed batteries to make the most of the product’s available space. This is why most battery manufacturers no longer bother certifying their off-the-shelf batteries.

RELATED: Understanding trademark law: intellectual property tips for inventors

RoHS

The RoHS certification guarantees that there is no lead content in the product. This particular certification is necessary for the electrical products sold in the state of California or the European Union. Since the economy of California is very sizeable, most of the products sold in the United States carry a RoHS certification.

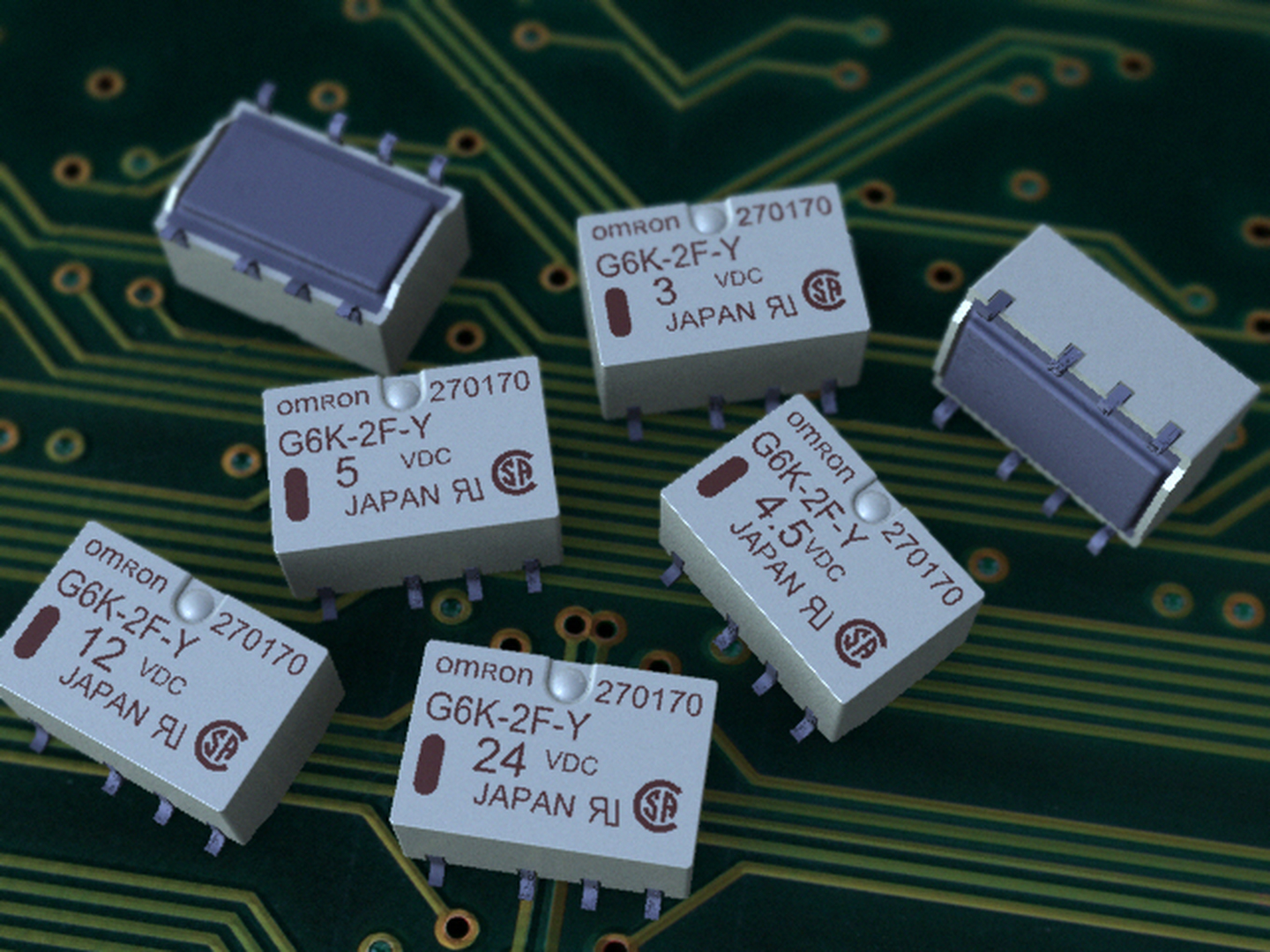

CSA or Canadian Standards Association/UL or Underwriters Laboratories

CSA or UL certification is necessary for all electrical products that plug into an AC outlet sold in the Canadian and US markets. CSA/UL certification is not required for battery-only products that aren’t plugged into an AC outlet. But many product liability insurance companies or major retailers will require products to have CSA or UL certification.

Top technologies used for prototyping new electronic hardware products

Now that you are familiar with the different phases of developing your new electronic hardware product, there are further, equally essential things you need to know. Among these are the technologies you can use to prototype your products. The good news is that numerous technologies are now at your disposal for creating your new hardware product’s prototype. These technologies are divided into two main categories. The first category relates to methods for prototyping the electronics part of your product, and the second includes the different technologies for prototyping the product’s enclosure.

RELATED: 3D Printing technologies for modeling and prototyping

You might want to start with the cheapest and simplest way to prototype your new product. From there, learn as much as possible as you strive toward a more production-quality prototype with each iteration. Here is a quick overview of some of the most common and popular methods you can use right now to develop your prototype, together with the things you will learn from them.

Computer numerical control or CNC machining

CNC machining is a subtractive process fundamentally different from the additive printing methods discussed below. CNC machining starts with a solid cube of metal or plastic. The computer-controlled tools will then remove the material to create the desired shape. You can think of this process as something that resembles a sculptor carving a statue.

While CNC machining isn’t as commonplace as 3D printing, it does offer several benefits. For starters, the parts can be made from either metal or plastic. The parts will also be more robust because they do not combine several layers, unlike additive printing. CNC-machined prototypes can also use the same plastic material that will be used for the higher production volume of injection molding.

RELATED: CNC programming costs & CNC machining service rates for companies

Electronic development kits

These development kits are ideal if you need to prove your product’s functional concept. Creating a POC prototype with a development kit is a good starting place for most products. This is especially true if you are curious about how your new product will fix the intended problem. Also known as development boards, development kits offer an excellent way to become more familiar with electronics. However, you must remember that these development kits also have limitations. One of these is that many are too expensive and large for mass production; therefore, you will eventually need to shift to a custom electronics design.

Electronic modules

The main advantage of electronic modules is that they are cheap and small enough to integrate into a product or system. These electronic modules have specific functions and are often soldered onto a PCB. Modules can be convenient when it comes to wireless functions. Wireless modules can lower the risk and cost of development and, simultaneously, the electrical certification costs. Modules can also make it possible to bring the product to the market more quickly.

RELATED: My new invention idea: how to design a product and get it made with companies

Clay or foam

Clay and foam are among the lowest-tech materials that you can imagine. However, you cannot just take these simple materials for granted. They can be the cheapest way for you to think through problems like the size and shape of a product. Simple materials such as clay and foam allow you to quickly come up with crude looks-like prototypes without spending anything at all. Clay and foam also allow you to experiment with how your product will feel when holding it in your hands. After you have finished working out the simple design choices, you can use more state-of-the-art technologies.

Fused deposition modeling (FDM)

Three primary prototyping technologies belong to the 3D printing category. FDM (fused deposition modeling services) is the most affordable, and it is the technology most frequently used for low-priced home 3D printers. Like the other 3D printing options, FDM is an additive process in which plastic gets added one layer at a time to create a prototype, with the plastic getting heated while passing through the nozzle. After the plastic is melted, it is deposited in layers fused together afterward. FDM has one downside: it lacks the capacity to reproduce fine detail. The prototype will ultimately not have the appearance and quality you can expect from the more expensive 3D printing technologies.

RELATED: New manufacturing materials: expanding the possibilities of product design

Injection molding

You will eventually migrate to making your plastic parts with injection molding technology, which is the only option for producing plastic parts in greater numbers. When it comes to using injection molding, the first thing you need to do is to form a mold using metal. The CNC machining process discussed earlier will be used to create this mold. The mold comprises two halves forced together to produce a cavity shaped like the required part.

High pressure is then used to inject the melted plastic into the mold. This pressure will allow the plastic part to have a very high level of fine detail. Even though injection molding is mainly utilized for mass manufacturing, this is your only choice to create a prototype that resembles your units for the final production. To save money, you can consider starting with cheaper aluminum molds to produce several thousand parts. You can then switch to molds that are made from much harder steels once there is an increase in your manufacturing volume.

RELATED: How to design products for injection molding & prototyping firms

Printed circuit board (PCB)

As mentioned earlier, two steps are involved in producing a PCB. A bare PCB is initially generated without the electronic components; the second step is to solder all the electronic components onto it. You will likely need to outsource your PCB prototype’s production because you can only produce the simplest designs at home. The good news here is a similar process is used for the high-volume production of the PCB. This can work wonders in significantly simplifying the transition to mass manufacturing of electronics from the prototype.

Selective laser sintering (SLS)

SLS (selective laser sintering services) is another additive process that belongs under the category of 3D printing. SLS printers use lasers to harden the powdered material one layer at a time. These SLS printers are too expensive and complex to be used at home. The primary benefit of SLS technology is that you can use it to produce prototypes that are made from metal as well as plastic.

Stereolithography (SLA)

Most of the time, enlisting the help of a stereolithography printing company is your best choice of technology for producing complex and high-quality prototypes. The main tradeoff here is that these SLA printers are significantly more expensive and complex, easily costing you several thousand dollars. This is why their use is mainly limited to professional prototype shops. Like FDM, SLA is an additive process; the difference is that SLA printers use UV or ultraviolet lasers for curing the resin. The liquid resin gets added one layer after another, and light is used to harden it.

The process is known as photopolymerization and can accurately produce prototypes with fine details. Stereolithography prototypes also have exceptional strength because of the chemical bonds between each resin layer. You can also expect a more professional appearance from SLA prototypes compared to the ones that FDM can produce.

The bottom line

The mere thought of launching a new electronic hardware product in the market can be thrilling. However, while gearing up to introduce your brilliant product idea, you must assess every dollar you spend carefully. Your main objective here is to get your product to market as cheaply and quickly as possible. You don’t have to worry a lot about lowering the manufacturing cost of your product during the early days, that is, as long as you know that you can earn profit later. Instead, your focus should be on minimizing the money you will spend on launching your product in the market.

How Cad Crowd can assist

Hopefully, this guide will give you a good idea of how to develop your new electronic hardware prototype and products, get them to the market faster, and enjoy more savings as you do so. And if you stumble on a roadblock, don’t hesitate to seek help from the experts at Cad Crowd, who can make the whole process easier and simpler for you. Contact us today for a free quote.

The post How to Develop a New Electronic Hardware Prototype & Products for Your Company first appeared on Cad Crowd.